_

CONTACT

ABOUT

PRESS

WORK

Ohm

Memento

Mars Bar

Straps

Mars Chair

Dot Dot Dot

Minerae

From Ash

Vann

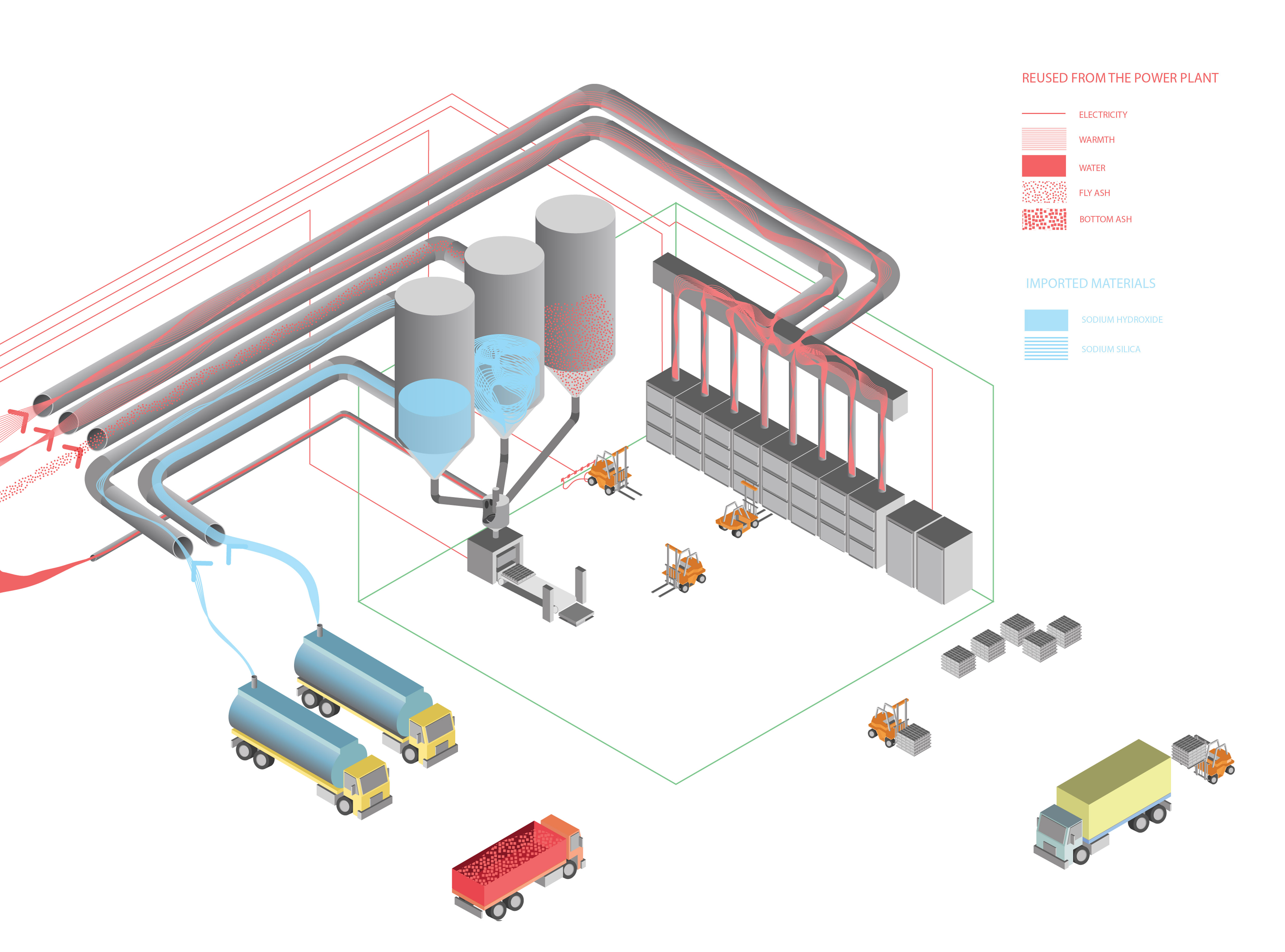

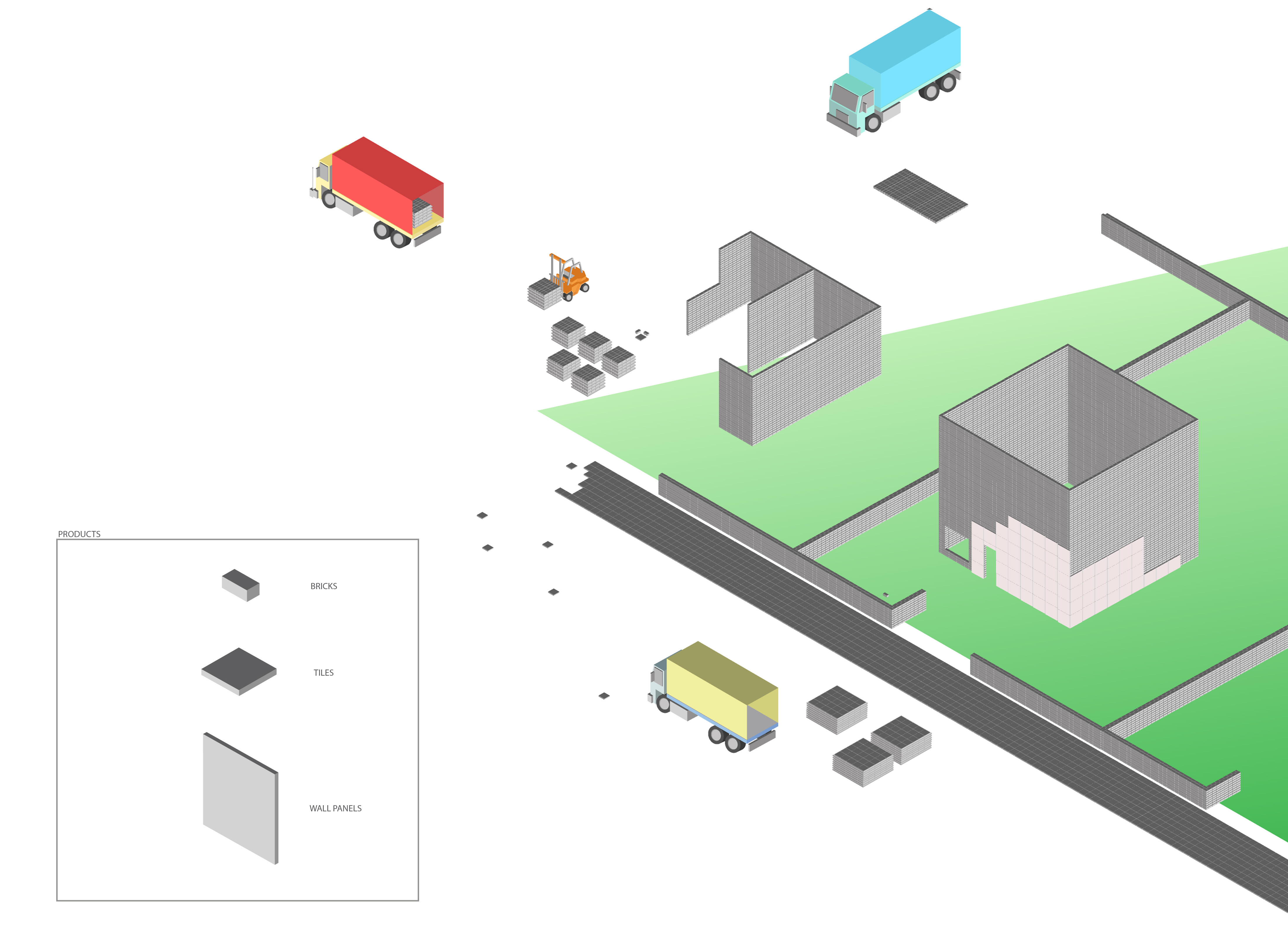

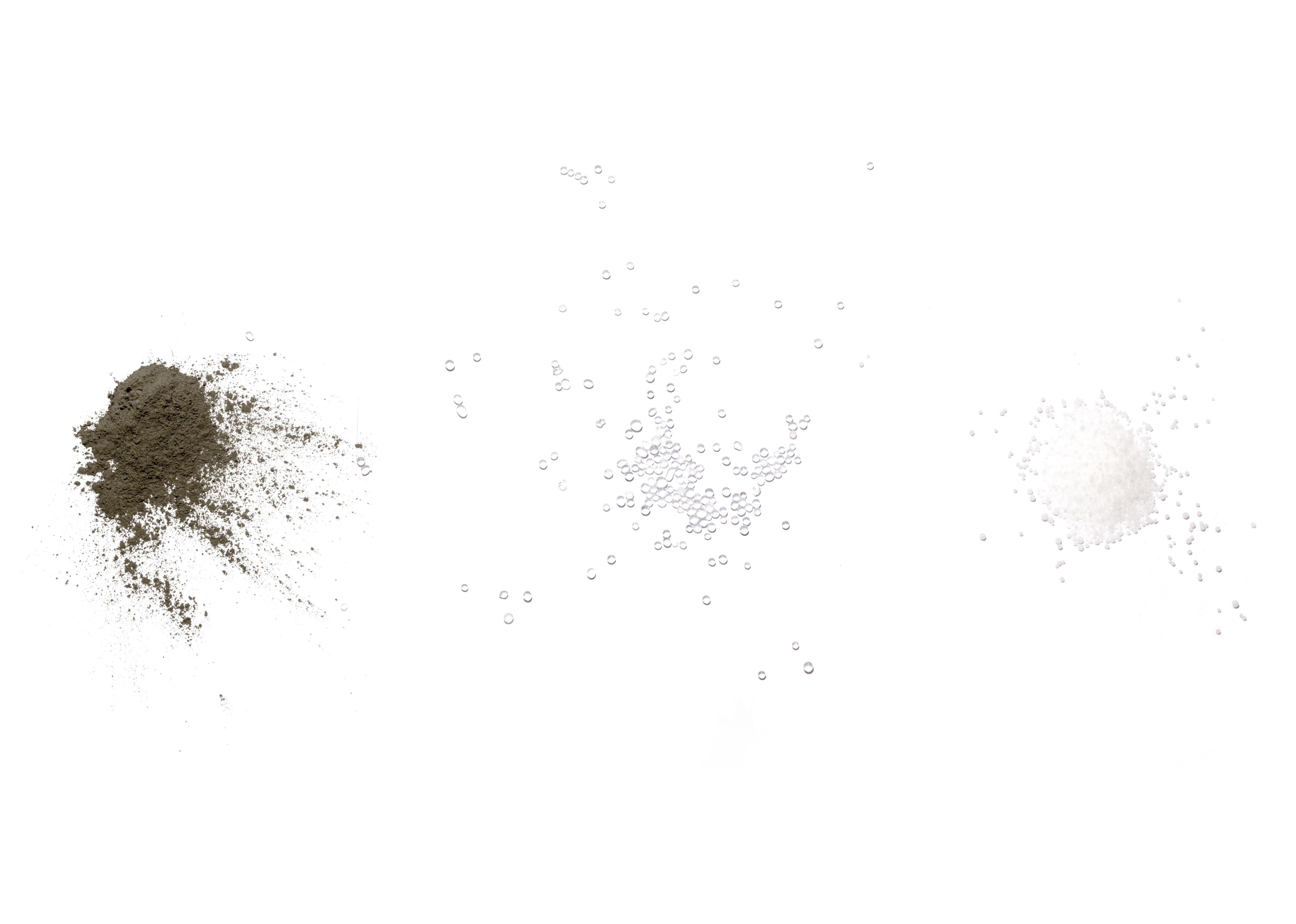

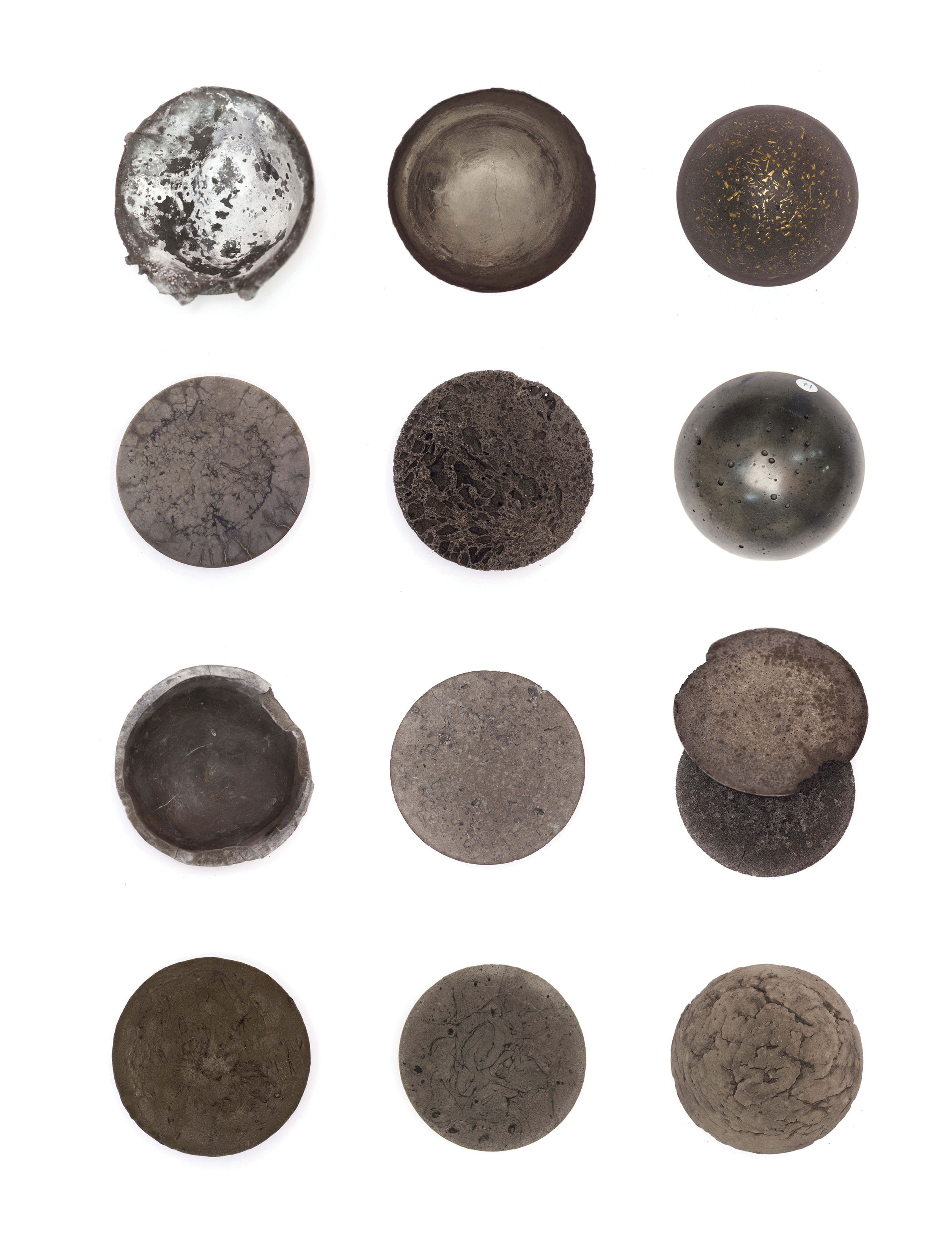

From Ash aims to use an ordinary energy waste as the central element of a new production process. In today's world of values and sustainability, the first source of energy comes from thermal power plants using coal as a fuel. This system is one of the most polluting energy sources, representing in 2015 44% of the global carbon emission (REF), but it is also one of the cheapest (REF) , explaining its widespread use all over the world with more than 1 500 coal-fired power plant (REF). Since the global energy demand is growing and this source is the cheapest, a thousand new plants are proposed for construction (REF), mainly in developing countries. Despite the global consensus on the reduction of coal as an energy source, the economic conjuncture offers to this fossil fuel some decades of intense use. Considering this reality, FROM ASH is presenting an economical and sustainable material for the afterlife of coal wastes. Those plants are creating energy by burning coal at high temperature. This high temperature followed by a fast cooling create some by-products including micro thin dust calledfly hash (REF). This fly ash represents around 75% of the coal ash, with a production of over 500 million tonnes a year for China (REF) and the U.S.A (REF)combine. The U.S recycles 40% of his fly ash as a binder for Portland concrete (REF) making the concrete cheaper and increase its mechanical properties. But most of the 60% left is wetted and store on site (REF). However raw fly ash is by itself the keystone of another kind of polymer, more resistant thermally, mechanically and chemically than Portland cement (REF) From Ash proposes fly ash based polymers as a sustainable consumer material. Those alkali-activated materials part of the geopolymer family (REF) can easily be made (REF) by using basic chemical components and become mechanically strong within few hours, allowing a simple production system everywhere near the thermal power plant. By doing so at least 80% of the materials come from the power plant.

|